With the rising of the modern industry and the internet technology, China rapid prototype machining is gradually acknowledged by the around world. The Internet of things (IOT) is a network based on the Internet, broadcast television networks, traditional telecommunication networks and other information carriers, enabling all ordinary physical objects that can be independently addressed to achieve connectivity.

Both on the supply side and demand side, driven by the Internet of things into represented by basic consumption industry and scale of development of the third wave, 5 G, low power consumption and other infrastructure to accelerate building the wan, trillions of new equipment will generate huge amounts of data, access network and artificial intelligence, edge calculation, new technologies, such as block chain speed combined with Internet of things, the application of hot spots, and the Internet of things in cross-border integration, integrated innovation and scale to a new stage of development.

Therefore, in such a rapid era of network interconnection, how to shorten the product development cycle and make adjustments to intelligent products according to the market response are particularly important. Many companies must have their ongoing machining projects for the product development.

Machining Solutions for Machining Projects

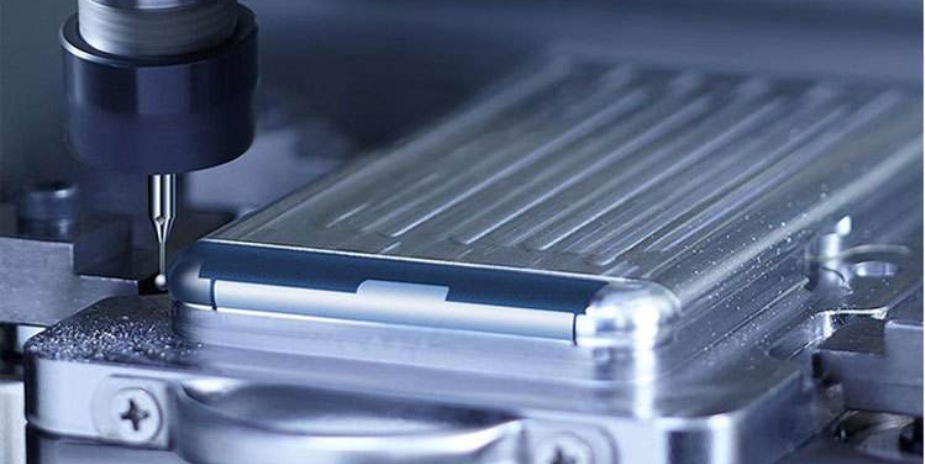

In the initial stage of product design or before it is officially put into the market, the prototype is usually made first for testing, and rapid prototyping technology such as CNC machining services meet this demand well.

CNC machining projects include turning projects and milling projects.

Turning projects will use lathe processing to machine the prototype. And the lathe processing is a part of mechanical processing. Lathe processing mainly uses turning tool to turn the rotating workpieces. Drilling, reaming drill, reamering, tapping, dying and knurling tools and other corresponding processing could be proceed on the lathe. Lathes are mainly used for machining shafts, disks, sleeves and other workpieces with rotating surfaces.

As for milling projects, it will usually go through ordinary milling or CNC milling. Milling is a mechanical machining method in which the cutter is used to process the surface of an object. Milling refers to the use of rotating multi-blade tool cutting workpiece, and is a high efficiency machining method. While working, the tool rotates (for main motion) and the workpiece moves (for feed motion). The workpiece could also be fixed, but in this way the rotating tool must also move for both main motion and feed motion. Milling machines can be divided into three kinds, include horizontal or vertical milling machine as well as a large gantry milling machine. These machine tools can be ordinary machine tools or CNC machine tools. Milling generally proceeds in the milling or boring machine, and is suitable for processing plane, groove, all kinds of forming surface and special shaped surface of the mold.

Materials for Machining Projects

There are two main types of processing materials, plastic and metal. Depending on the needs of the project, the developer can specify different materials. Also, experienced suppliers who provide CNC services will advise the customers according to their needs and select the corresponding machinable materials. The common used material for CNC machining projects are ABS, PC, PP, PA, POM and so on. As for the metal material, aluminum alloy, steel, copper, zinc alloy, magnesium alloy will be the common choices

Last but not least, to develop products better, developers need to have a good CNC services provider to meet their CNC machining projects. First, the vendors must be capable enough to respond quickly and meet the developer’s needs exactly. Second, the partner must be a professional one who understands the needs of the developer and can advise on the production feasibility of the project when needed.

Leave a Reply